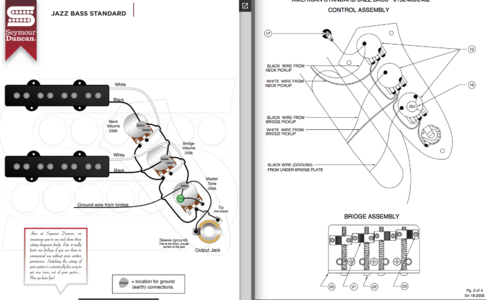

In mass production, it is very common to cut corners, in order to keep costs low. This is what Fender often does with their grounding schemes. The pots and output jack are mounted on a metal control plate, which provides a connection to ground. This is perfectly adequate in the short term, but it is preferable to have dedicated soldered wires, like the Seymour Duncan diagram shows, so that the grounds will be reliable if either the nut on a pot/jack comes loose, or the metals corrode. If you are doing your own wiring job, be sure to use soldered connections for your grounds.

As for the lug, that is there to ground the conductive shielding paint that is in the control cavities, since you cannot solder to it. If you are doing your own wiring job with copper tape, then you can solder directly to the copper. Paint will always require a ground lug, however.