Okay so I did the final coats (pics to come).

Having trouble getting a signal from the piezo. I know that with magnetic pickups, you can just tap the pole pieces with a screwdriver to see if it makes a sound when plugged in. I didn't notice any sound coming out when I tapped the piezo saddles.

I also tried taking a string, pulling it through the bridge, held the string taut and 'strummed' it it to see if I could get a tone. I still did not hear anything through the amp (I don't have the neck screwed in otherwise I would have just strung it up the normal way).

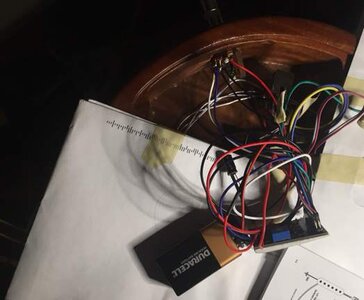

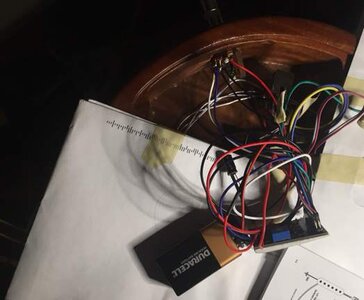

I attached pics, maybe you guys can see where I went wrong? Please note, these are not the prettiest solder joints, they are literally the first that I have ever done.

I also attached the diagram from the manual showing what color wires need to go in what spot. I double and triple checked, and it seems like I put everything in the right place. I must be missing something?

As a last ditch effort, I tried turning the volume knob (the only pot I have installed) clockwise and counterclockwise just to make sure it wasn't turned all the way down, but still no luck.

Lastly, I know that the area by the input jack looks like hell. I didn't make the wood thin enough for the input jack so I had to dremel it back from inside the control cavity, hence the ugliness. Just try not to look at it, it will be covered almost always, I know it's hard to deal with.

The biggest difference that I see is that the pot that I'm using doesn't have a little cylindrical thing (it's a push-pull pot), so I didn't apply a ground wire there. Could that be it?

Also please note, I don't have any quickswitch, or magnetic pickups on this bass, so you can ignore that part of the diagram.

EDIT: still doesn't work, but I realized that the battery was not attached to the PC board properly (it was backwards). Like I said, this did not fix it, but at least I caught it. Otherwise, all of the wiring is good to my knowledge.