I’m thinking 600 would load up immediately. I think 320 or 400 non loading sandpaper (the white stuff) would work fine. Doing a lot of sanding brings with it the possibility of your dots getting “contaminated “ with the dark dust. Which could actually be cool if you like the more aged look.Yes this is true. I’ll take a super light approach on sanding maybe spot check an area with 4-600 grit.

Enjoy the benefits of a premium membership!

Upgrade Account

-

Welcome to TalkBass! Want to remove ads? Register an account and login to see fewer ads, and become a Supporting Member to remove almost all ads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

More options

Who Replied?What you have is wood grain running in the wrong direction. It is a natural imperfection in the wood and there is absolutely nothing wrong with your fingerboard except your dots look fuzzy and the fret slots are not deep enough as well as not wide enough. If you are bugged about the reverse grain you can use some filler made for open pore wood in a matching color. As the directions state you let it dry then wipe it off but you may need another application. Please stay away from CA or epoxy and dust because you will wind up with a mound of rock hard glue dust and when you sand it you will likely pull out the fix or sand a flat spot into you fingerboard. Use motor oil to dress the fretboard at completion.

Christopher DBG

Commercial User

- May 18, 2015

- 883

- 2,931

- 4,916

- 58

- Disclosures

- Luthier/Owner, Christopher Bass Guitar

That's also called interlocking grain. Most trees grow with some degree of twist or spiral like a candy cane, not perfectly straight. Most of the time the tree grows it's whole life with the spiral going in one direction. Sometimes though the direction of the spiral reverses, so a tree may start out growing with a clockwise twist for 20 years, then suddenly switch to counter-clockwise twist for the next twenty, then switch back or grow straight for a while. Unfortunately when you get tearout like that in a dense tropical wood if often goes a lot deeper than it looks like on the surface and takes a lot of sanding to get rid of. Tough to tell, the first pic looks bad but the next ones not so bad. I would think if LMI is selling radiused boards that are supposed to be nearly ready to use they would not leave tearout like that.

That's also called interlocking grain. Most trees grow with some degree of twist or spiral like a candy cane, not perfectly straight. Most of the time the tree grows it's whole life with the spiral going in one direction. Sometimes though the direction of the spiral reverses, so a tree may start out growing with a clockwise twist for 20 years, then suddenly switch to counter-clockwise twist for the next twenty, then switch back or grow straight for a while. Unfortunately when you get tearout like that in a dense tropical wood if often goes a lot deeper than it looks like on the surface and takes a lot of sanding to get rid of. Tough to tell, the first pic looks bad but the next ones not so bad. I would think if LMI is selling radiused boards that are supposed to be nearly ready to use they would not leave tearout like that.

The second set of pics better represent how it looks in normal lighting. The first pic I took was very close up in direct sun light.

I think I should be able to smooth it well enough. I’ll have another look at it tonight and see. I’m deliberately taking my time on this

Thanks!

At this point it’s really just a cosmetic issue. If there really is a spiral grain internally you could sight down it periodically to see if there’s any twisting going on but I think you’d be very unlucky if that happened. A few minutes sanding with a block and full length strokes and you’ll be good to go. As I mentioned, after fretting, oiling and the passage of time you won’t likely notice it or even remember it. Live and learn.The second set of pics better represent how it looks in normal lighting. The first pic I took was very close up in direct sun light.

I think I should be able to smooth it well enough. I’ll have another look at it tonight and see. I’m deliberately taking my time on this

Thanks!

Hey All,

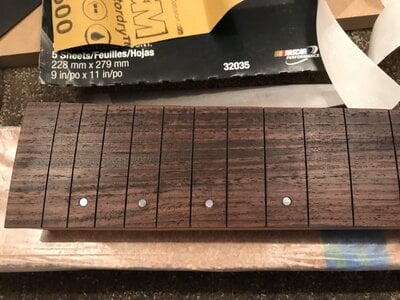

In believe I’m all good now with the RW FB.

The chatter or whatever can’t hardly be felt after sanding lightly up to 2000 grit and a radius block.

May not be able to see but here’s a few pics

(A little wet with Naptha)..

I did also learn one other thing when doing the dots and addressing spots filled with rosewood dust, I have a new friend called super solvent . Really good at getting off the excess.

. Really good at getting off the excess.

Off to check on fretting now...

Thanks everyone!

In believe I’m all good now with the RW FB.

The chatter or whatever can’t hardly be felt after sanding lightly up to 2000 grit and a radius block.

May not be able to see but here’s a few pics

(A little wet with Naptha)..

I did also learn one other thing when doing the dots and addressing spots filled with rosewood dust, I have a new friend called super solvent

Off to check on fretting now...

Thanks everyone!