Enjoy the benefits of a premium membership!

Upgrade Account

-

Welcome to TalkBass! Want to remove ads? Register an account and login to see fewer ads, and become a Supporting Member to remove almost all ads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Crazy, crazy guitar/bass ideas - prototypes

- Thread starter reverendrally

- Start date

More options

Who Replied?When I'm hanging out with my brother, my wife always complains that I muck up... which is true.

Coz cupholders. Don't worry I'm only messing with you. I'm really not a big drinker.

In other news. I got the brass inserts out for the adjustable bridge. With pliers.

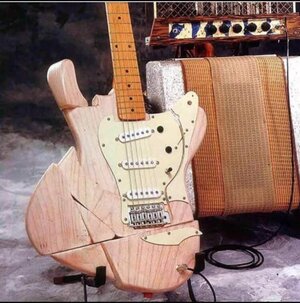

But don't cry. This guitar body deserves to be set on fire now. Heck, we may even do so this evening. It's terrible, terrible plywood. It astounds me that the fingerboard is exotic timber.

Coz cupholders. Don't worry I'm only messing with you. I'm really not a big drinker.

In other news. I got the brass inserts out for the adjustable bridge. With pliers.

But don't cry. This guitar body deserves to be set on fire now. Heck, we may even do so this evening. It's terrible, terrible plywood. It astounds me that the fingerboard is exotic timber.

With the fretless done, I pulled this poor old thing out again today. Some crazy Italian 1960's trussrod end in there...

Lots of crazing (just like me) in the nitro. A part of me wants to fix them.

The frets were very worn out. I can't see how you could have reground them. So soldering iron and chisel and out they came.

I got out my radius blocks and gave it a good sand. The first 2 bits of sandpaper were just clogged with grease and nastiness. Then I finally got the the timber. I could go a little lower on the bass side, but I think it's good for now. Wenge dust is not a lot of fun is it.

Unfortunately, the Wenge board is really dry and brittle. I lost the bass side corner of the board just above the zero fret. Had to superglue it back on. It also tended to lift and chip out around the fret tangs. I was being super careful too. Hopefully that won't show under the new frets. Once I've got the new frets in, I'll give it a really good oil. Here's hoping that will protect it into the future.

BTW, the machine heads have a light coat of rust. What can put them in to clean that off? Vinegar?

Lots of crazing (just like me) in the nitro. A part of me wants to fix them.

The frets were very worn out. I can't see how you could have reground them. So soldering iron and chisel and out they came.

I got out my radius blocks and gave it a good sand. The first 2 bits of sandpaper were just clogged with grease and nastiness. Then I finally got the the timber. I could go a little lower on the bass side, but I think it's good for now. Wenge dust is not a lot of fun is it.

Unfortunately, the Wenge board is really dry and brittle. I lost the bass side corner of the board just above the zero fret. Had to superglue it back on. It also tended to lift and chip out around the fret tangs. I was being super careful too. Hopefully that won't show under the new frets. Once I've got the new frets in, I'll give it a really good oil. Here's hoping that will protect it into the future.

BTW, the machine heads have a light coat of rust. What can put them in to clean that off? Vinegar?

I'm thinking big dovetail, if it fits your definition of pocketless.

+1

Yep, tear them down and soak the rusted parts in vinegar. Works like a charm.BTW, the machine heads have a light coat of rust. What can put them in to clean that off? Vinegar?

Yep, tear them down and soak the rusted parts in vinegar. Works like a charm.

How long for?

Just found this one, Rev. Seems we got some similar, though different, ideas. In answer to your first question, the traditional approach was 3" nails and glue on a butt-joint. Worked fine for lutes, theorboes, and the like for centuries. String tension was lower, though

A few hours (probably around 4). It's been a while since I did it. Followed it up with metal polish.How long for?

Here's the thread where I did it: Restoring a 196? National Violin Bass

It was a popular MIJ feature in the 60s. Alas that neck will be replaced, since it has a sideways bend. I'll probably build a new one out of maple and reuse the fretfboard.

You can also try electrolysis for rust removal, like here:

I cleaned a lot of tools, like old chisels and auger bits in vinegar. Rust gets removed, but the side effect is that the steel darkens a lot and gets a matt surface. I used machine oil to protect the tools. Never tried vinegar with guitar hardware though, so I don't know how it affects it or how it affects chromed elements for instance.

I cleaned a lot of tools, like old chisels and auger bits in vinegar. Rust gets removed, but the side effect is that the steel darkens a lot and gets a matt surface. I used machine oil to protect the tools. Never tried vinegar with guitar hardware though, so I don't know how it affects it or how it affects chromed elements for instance.

The old tool group I used to read more was very into electrolysis (and it certainly worked far better than anything I'd ever used before) but got a bit leery due to hydrogen embrittlement (which can be mitigated, and is mostly of concern with hardened and high-carbon steel, so edge tools, mostly) and moved on to citric acid being more popular - in either case you need to rinse well and dry the item quickly or rust will start right back up. Mitigating the hydrogen is primarily a matter of extending heating to dry for a while longer than it takes to just dry, without going so hot as to ruin the temper. A purported advantage of citric acid is that it is unlikely to eat good steel in any reasonable time, but does effectively remove rust. Electrolysis really does just eat the rust and leave the steel alone, but it may not be kind to plating.

My proof of concept tool for electrolysis was a pair of pliers I picked off the side of the road one spring. I live where there is winter, and the roads are salted in winter. This pair of pliers was solidly frozen, immobile, heavily rusted. After a while (12 hours? more?, I don't recall) in the tank, they moved freely - very freely, as a good part of the pivot pin had turned to rust, and bulk rust ends up in solution when removed electrolytically. So they are not great pliers, but they are far better than the junk they were as found, and I would never have gotten there with naval jelly, in my experience of naval jelly (lots, all disappointing.)

My proof of concept tool for electrolysis was a pair of pliers I picked off the side of the road one spring. I live where there is winter, and the roads are salted in winter. This pair of pliers was solidly frozen, immobile, heavily rusted. After a while (12 hours? more?, I don't recall) in the tank, they moved freely - very freely, as a good part of the pivot pin had turned to rust, and bulk rust ends up in solution when removed electrolytically. So they are not great pliers, but they are far better than the junk they were as found, and I would never have gotten there with naval jelly, in my experience of naval jelly (lots, all disappointing.)

Last edited:

So, had a blonde moment. Meant to wipe naptha onto the fingerboard. Picked up the wrong bottle and wiped Mineral Turps instead.

I've cleaned most of it off with naptha, but I wondering if there's something else I should do? Just let the turps evaporate? I'm concerned about the glue not working when I refret the neck. Hmm.

I've cleaned most of it off with naptha, but I wondering if there's something else I should do? Just let the turps evaporate? I'm concerned about the glue not working when I refret the neck. Hmm.

They call it mineral turps Down Under, but up here we call it mineral spirits, or white spirits.  Rev, you should be fine, I imagine once it evaporates you'll be good. Many finishes and varnishes contain mineral spirits as a solvent anyway. If you're concerned, maybe put a little mineral turps on a tester piece and then follow up with your planned finish. Then you might have a good sense as to what is going to happen.

Rev, you should be fine, I imagine once it evaporates you'll be good. Many finishes and varnishes contain mineral spirits as a solvent anyway. If you're concerned, maybe put a little mineral turps on a tester piece and then follow up with your planned finish. Then you might have a good sense as to what is going to happen.