- Jun 30, 2010

- 44,638

- 194,352

- 11,987

- Disclosures

- musician/artist/owner - Gildaxe

I hacked out new cavities with a forstner bit. It was my first time and it was very pleasant. I hacked down the peaks a bit with the worst chisel on Earth, and it's ready for test fitting!

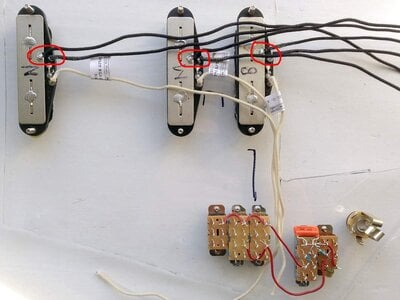

View attachment 1027947 View attachment 1027948 View attachment 1027950

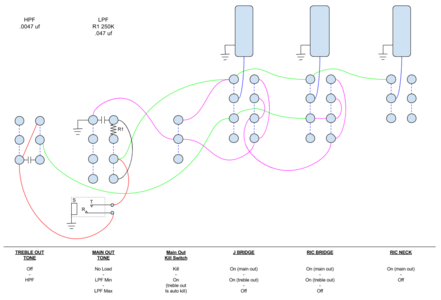

Next I get the switches and jack fitted on plexi, wire it up, and find out how much damage I have to undo.

View attachment 1027953

That's turning out really cool!